Products

Products

Pressure Boosting Pump

Application

Shower Panels

Apartments, Bungalows, Small resorts and Hotels

RO Plant

Garden Irrigation & Fountains

Household and commercial water supply

Heating and washing system

Function

The Pressure Booster System consists of a multistage centrifugal pump suitably assembled with automatic pressure control (Pressure guage, Pressure switch brass NRV and Brass five way connector) and Pressure tank. The pressure Booster system is suitable where the main supply lines have low pressure and wherever boosting is required and wherever pressure need to be maintained. The pump will automatically switch ON/OFF to maintain the output pressure.

Salient Features |

Benefits |

Stainless steel Diffusers and Impellers |

Noiseless, wear resistance |

Stainless steel shaft |

Low maintenance, extended pump life |

Ceramic and graphite mechanical seal |

|

Precisely Designed winding |

Designedfor high start / stop per hour (75 per hour) |

Thermal-cut out relay |

Provides winding protection |

Insulation class F |

To improve winding insulation |

Protection IP 44 |

Prevents dust & Spillage of water |

Improved vertical tank with pressure switch |

Auto ON and OFF. |

Technical Data |

||||

Flow Q |

max 160 lpm |

|||

Head H |

max 60 mtr |

|||

Liquid temp |

up to 60 Deg C |

|||

Suction Lift |

up to 7 mtr |

|||

Power supply |

220 - 240V, 50Hz |

|||

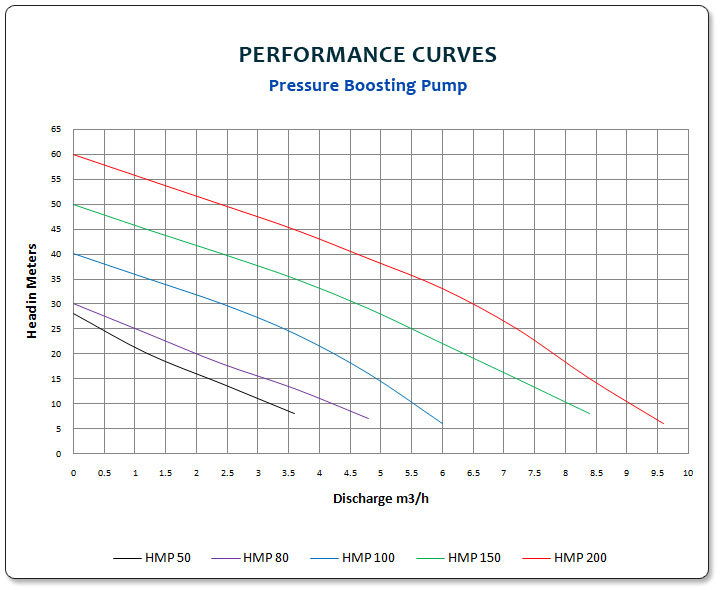

Performance Table and Chart For Multistage Pump |

||||||||||||||

Model |

Power |

Pipe size |

m3/h |

0 |

1.2 |

2.4 |

3.6 |

4.8 |

6 |

7.2 |

8.4 |

9.6 |

||

kW |

HP |

Suction |

Delivery |

l/min |

0 |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

160 |

|

HMP 50 |

0.37 |

0.5 |

1" |

1" |

Head in Meter |

28 |

20 |

14 |

8 |

|||||

HMP 80 |

0.60 |

0.80 |

1" |

1" |

30 |

24 |

21 |

17 |

6 |

|||||

HMP 100 |

0.75 |

1.00 |

1" |

1" |

40 |

34 |

30 |

26 |

16 |

6 |

||||

HMP 150 |

1.10 |

1.50 |

1" |

1" |

50 |

40 |

37 |

33 |

29 |

24 |

10 |

|||

HMP 200 |

1.50 |

2.00 |

1" |

1" |

60 |

50 |

48 |

43 |

37 |

30 |

24 |

15 |

6 |

|

Accessories For Pressure Boosting System

Hydro Pneumatic Pressure Tank or Pressure Vessel

The Pressure Booster System consists of a multistage centrifugal pump suitably assembled with automatic pressure control (Pressure guage, Pressure switch brass NRV and Brass five way connector ) and Pressure tank. The pressure Booster system is suitable where the main supply lines have low pressure and wherever boosting is required and wherever pressure need to be maintained. The pump will automatically switch ON/OFF to maintain the output pressure.

Pressure Switch

Pressure switch is an electro-mechanical device that senses changes in pressure and provides electrical contact closures at predetermined pressure values when connected in the pressure boosting system. The cut in and cut out of pressure values can be preset with the help of pressure gauge. The switch on and switch off the pump depends upon the inline pressure.

Pressure gauge

It shows the inline pressure. The cut in and cut out of pressure values can be preset with the help of pressure gauge.

Five- way connector

To connect all the above accessories Five-way connector is used.

Non-Return Valve

These valves are very useful in preventing back flow of water to the pump. These valves have minimum head loss and can be very competitive in terms of long service life. These valves are very useful in waterworks pipelines to reduce hammer effect. Non slam and quick closing characteristics have made this product a very demandable one across markets.

Y- Strainer

Y-Strainers are devices for mechanically removing unwanted solids from liquidby means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps from solid dust and waste materials entering the pump.